The 6-Second Trick For Bullcaster Co.,ltd

Wiki Article

Indicators on Bullcaster Co.,ltd You Should Know

Table of ContentsAn Unbiased View of Bullcaster Co.,ltd5 Simple Techniques For Bullcaster Co.,ltdGetting The Bullcaster Co.,ltd To WorkBullcaster Co.,ltd Can Be Fun For AnyoneThe Definitive Guide for Bullcaster Co.,ltd

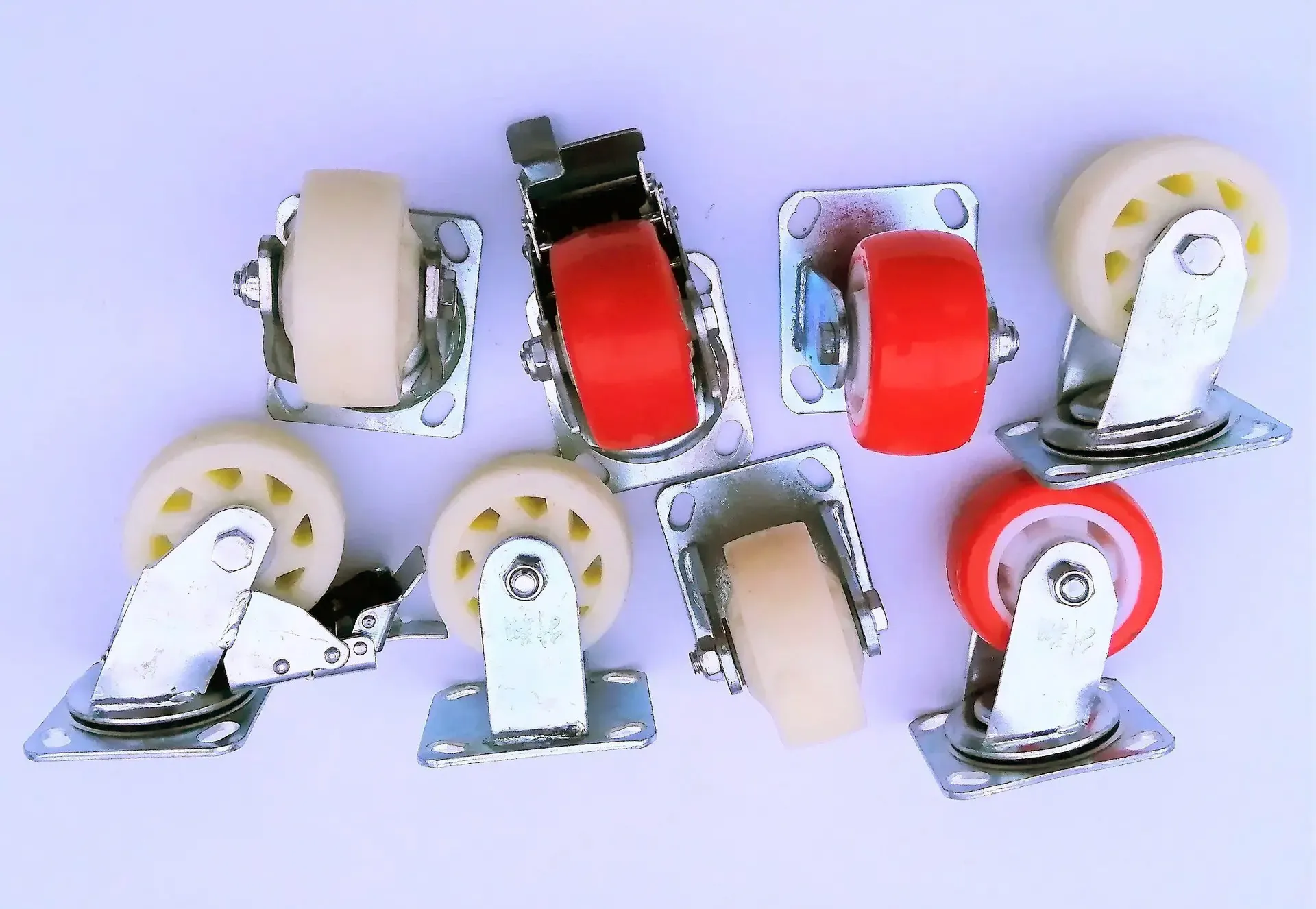

One of the most usual kind, plate casters are identified by a level, square-shaped installing surface. They typically have four holes one on each edge of the placing surface area which are used to secure the plate caster to the object. They are called "plate casters" since the placing surface area resembles as a square-squared plate (industrial casters).

If a workbench with wheels is put on a sloped surface, for instance, it may roll downhill unless the wheels are secured. Locking casters use the flexibility to lock the wheels in area, consequently stopping the object on which they are placed from rolling or rotating.

While plate casters have flat, square-shaped placing surface area, stem casters include a cylindrical-shaped pole for placing. In the photo presented above, the wheel in the center is a stem caster.

Unknown Facts About Bullcaster Co.,ltd

Hollow Authority casters are defined by a stemless layout with an opening on the top of the placing surface - heavy duty casters. To install a hollow Kingpin caster, the caster is positioned against the item, after which a fastener like a screw or bolt is driven with the opening and also right into the things.Unlike various other wheels, inflexible wheels can not swivel in a complete 360-degree variety. Instead, they can just roll forwards and also backwards. Stiff wheels are typically more powerful than traditional wheels, however their minimal series of motion makes them a bad selection for sure applications. Monroe has a wide array of wheels that cover every application.

Caster wheels are used in buying carts, workplace chairs, medical beds, and also material handling tools. Caster wheel variations differ considerably based on the application demands as well as are extensively utilized in a large range of applications. It is a remarkable mobility enabler, with properties such as strength, corrosion resistance, water resistance, as well as weather condition resistance.

Some Of Bullcaster Co.,ltd

Heavy products require wheels with thicker wheels, some bigger objects may require numerous wheels to equally distribute weight. This section will talk about the manufacturing processes involved in making caster wheels. The first plate to be cut is the top plate. This is the plate utilized to install the wheel below the things, as an example the industrial cart.Plasma cutting is a kind of pop over to these guys thermal cutting that uses an ionized gas to reduce the metal. https://about.me/bullcasterco. This means that the procedure utilizes warm to melt the metal instead than mechanically reducing it. It is among the most common methods for cutting thick steel plates, yet it's likewise helpful for sheet metal.

Forks are the arms that hold each side of the wheel axle (casters China). The forks are made out of steel coil, an extra flexible and also thinner type of steel.

Journalism bends the piece right into the needed form and it additionally makes a circular groove around the opening in the center. The hole is loaded with steel ball bearings that permit the yoke to swivel. A steel retainer is fitted to hold the sphere bearings in position. The grooves of the steel cap are filled up with round bearings as well after that they position it onto a punch press and also place the yoke ahead.

The 2-Minute Rule for Bullcaster Co.,ltd

The following machining procedure on the manufacturing of wheel wheels is the extrusion of the wheel product. To make the wheels, nylon inserts are needed.The rubber side takes in shock, minimizes noise, as well as stops damage to the floor or surface. For bigger sized wheels, a different molding press is made use of to match the called for dimension. The molding process to produce the wheel coincides. These larger molding press machines usually make one wheel at a time.

The steel guides position the wheel in between the yokes as well as place the steel wheel axle. A bolt head safeguards one end as well as a nut is connected to the other end. Oil is injected to lubricate the round bearings. The wheel needs to go through a series of quality assurance examinations that count the number of revolutions a wheel can stand up to before it ultimately damages.

A swivel caster, on the various other hand, may be a far better option if there's requirement for even more ability to move. Consider additionally whether there's requirement for swivel locks, if equipment is to be relocated a straight line. The ability to relocate something is why casters are placed on it, however there's also require to know just how much flexibility there remains in that motion.

Bullcaster Co.,ltd Things To Know Before You Get This

Lots of applications need a stem placed wheel, although this can limit the caster's weight capability. Durable wheels will certainly make use of a plate mount to protect the caster and also spread the lots over a greater mounting area. Understanding the placing choice can aid narrow down the options when selecting casters from a substantial number.Report this wiki page